Now that I’m driving the Jeep every day, I’m starting to notice small things that will need attention. For example, the brake pedal is so close to the accelerator pedal (and both are loose) that pressing on the brake can press on the accelerator at the same time.

Category Archives: My Jeep

Jeep: First check-up

Most people who buy or restore an old vehicle don’t plan on making it their “daily driver,” for a lot of practical reasons. Reliability, comfort, financial… just to name a few. But for the last few years I’ve driven the Land Rover or the pickup every day. Leaving a cherished vintage vehicle in the garage would be like having a good dog you never played with. So when I added the Jeep to my little fleet, I knew I wanted to drive it regularly so a trip to the mechanic was high on my list. Just to make it safe-ish to drive. After an agonizing six weeks I got the Jeep back this week.

Most people who buy or restore an old vehicle don’t plan on making it their “daily driver,” for a lot of practical reasons. Reliability, comfort, financial… just to name a few. But for the last few years I’ve driven the Land Rover or the pickup every day. Leaving a cherished vintage vehicle in the garage would be like having a good dog you never played with. So when I added the Jeep to my little fleet, I knew I wanted to drive it regularly so a trip to the mechanic was high on my list. Just to make it safe-ish to drive. After an agonizing six weeks I got the Jeep back this week.

- Lube, Oil and Filter change

- Replace front and rear differential oil

- Replace steering bell crank

- Replace drag link repair kit

- Replace headlight switch

- Replace brake light switch

- Replace brake master cylinder

- Adjust radiator fan

- Reseal right rear wheel (losing air due to rust on bead)

The parking brake doesn’t work and the oil pan is leaking bit so we’re not quite finished but it’s about as good as we can make it for now.

Jeep “carport” ver. 2

Jeep has crack in engine block

Took the Jeep to my mechanic for four routine service and maintenance. Oil change, lubrication, etc. Probably been a while. Alas, he found a crack in the engine block. The plan is patch with StopLeak, J-B Weld, etc. I won’t be driving it fast or far and if/when it stops running we’ll look at replacing the block. As far as I can tell, almost all old Jeep blocks have a crack (or soon will). On the bright side, replacing an engine on a CJ-2a is as simple as it gets. And the Jeep won’t be my daily driver, just for fun in the sun. And we just need to keep the Jeep running as long as I am. A lowering bar.

Farming with a Willys Overland Jeep farm tractor

This promotional video (almost 25 min!) illustrates just how hard Willys was pushing the CJ series as a farm (and industry) tool.

“Now it’s a Truck… Now it’s a Tractor… Now it’s a Runabout… Now it’s a Mobile Power Unit.”

“Willys claimed the Jeep could “pull a 5,500-pound load on the highway at a good speed.” The company also claimed the Jeep could “do the job of two heavy draft horses operating at a speed of 4mph, 10 hours a day, without causing the engine to overheat.”

Can’t find a date on this film but probably late 40’s or early 50’s, so would have been shown in movie theaters.

“Perceived safety”

UPDATE: After a little more thought and some measurements, I cancelled this order. These straps look kind of cool but wouldn’t make me any safer.

When I purchased the Jeep there were a couple of vintage seat belts tucked under the seat. Maybe from a 70s era Chrysler? They were ugly and didn’t look safe so I removed them.

After riding around in a vehicle with no doors, seat belts seemed like a sensible idea so I purchased a set. (Paul called them “perceived safety.”) After struggling to install them I decided I did NOT need seat belts and put them back in the box. No turn signals, no seat belts! Then I started seeing photos and video of military era Jeeps with “safety straps.”

Looks like they might keep an old guy from tumbling out of the Jeep and I’ll settle for that. And in the event I’m surprised by a German patrol, I do NOT want to fuck with a stuck seat belt latch.

Looks like they might keep an old guy from tumbling out of the Jeep and I’ll settle for that. And in the event I’m surprised by a German patrol, I do NOT want to fuck with a stuck seat belt latch.

“Is my Jeep trying to kill me?”

A much better “drive” video than mine. Favorite line: “You drive this with the anticipation anytime, anything on this road is going to kill you.”

Jeep: Plugging Holes

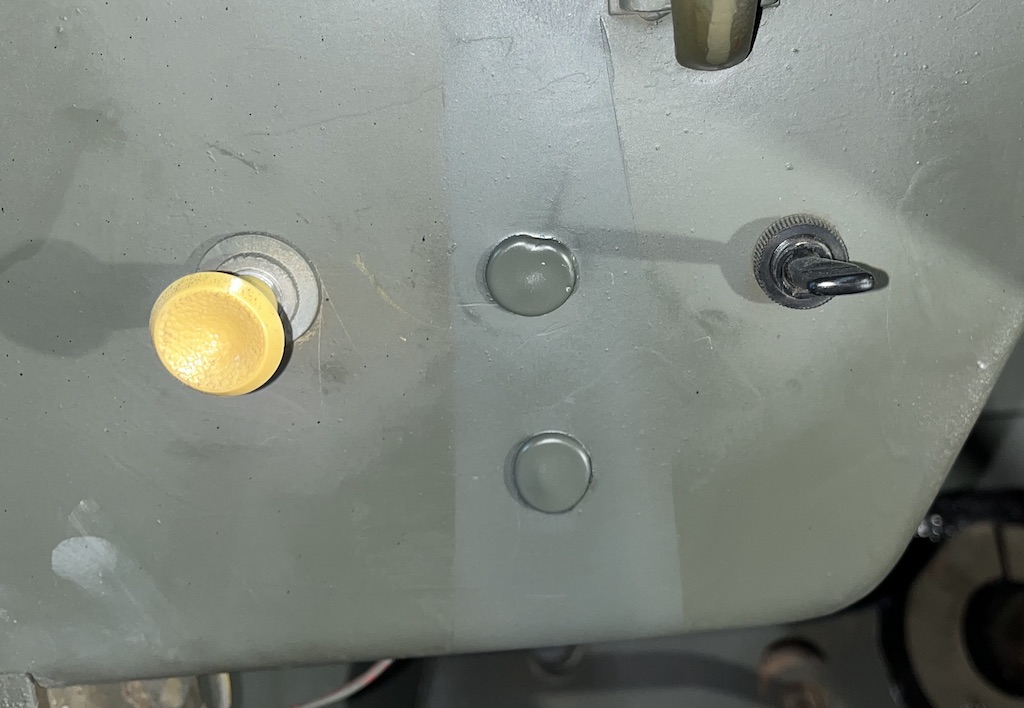

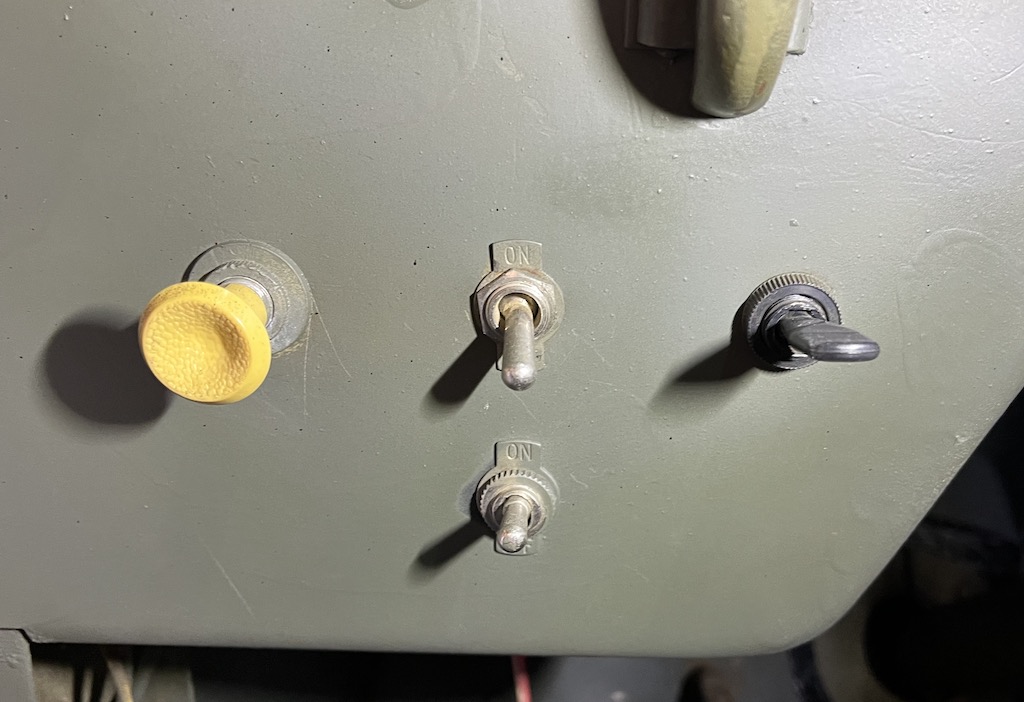

Previous owners of the Jeep had added some switches that no long switch anything, so I removed them. Leaving some unsightly holes. (first two photos)

The black rubber grommets didn’t look bad but there was still a little camo paint left so…

Sloppy paint job but after the Jeep gets some hot sun this summer, I’m hoping for a nice even fade.

Jeep: Tracing Wires

My beloved Land Rover has spent the last day and night outdoors to make room for the Jeep. A temporary move, I promise.

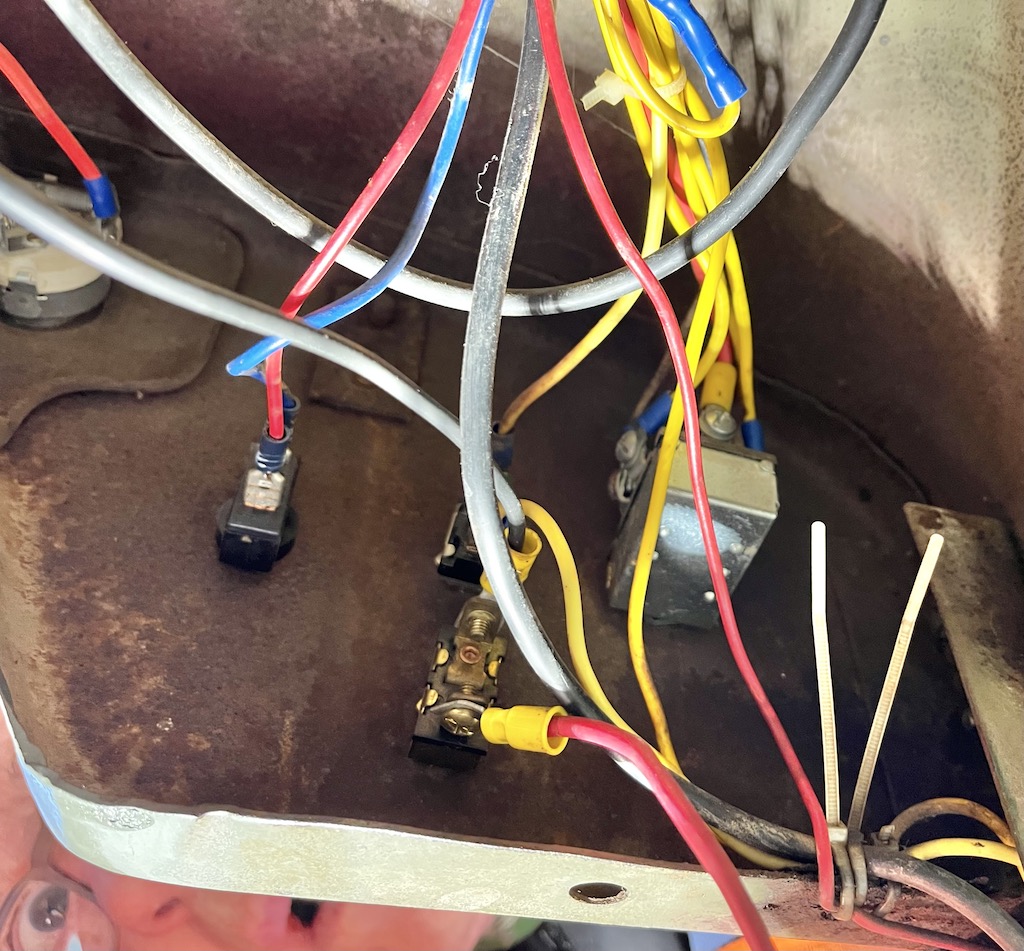

There are a few mystery switches on the Jeep so I decided to see if I could trace the wires back to something no longer needed.

There’s a real rat’s nest of wires behind the dash and I might –or might not– try to tidy up.

There’s a real rat’s nest of wires behind the dash and I might –or might not– try to tidy up.

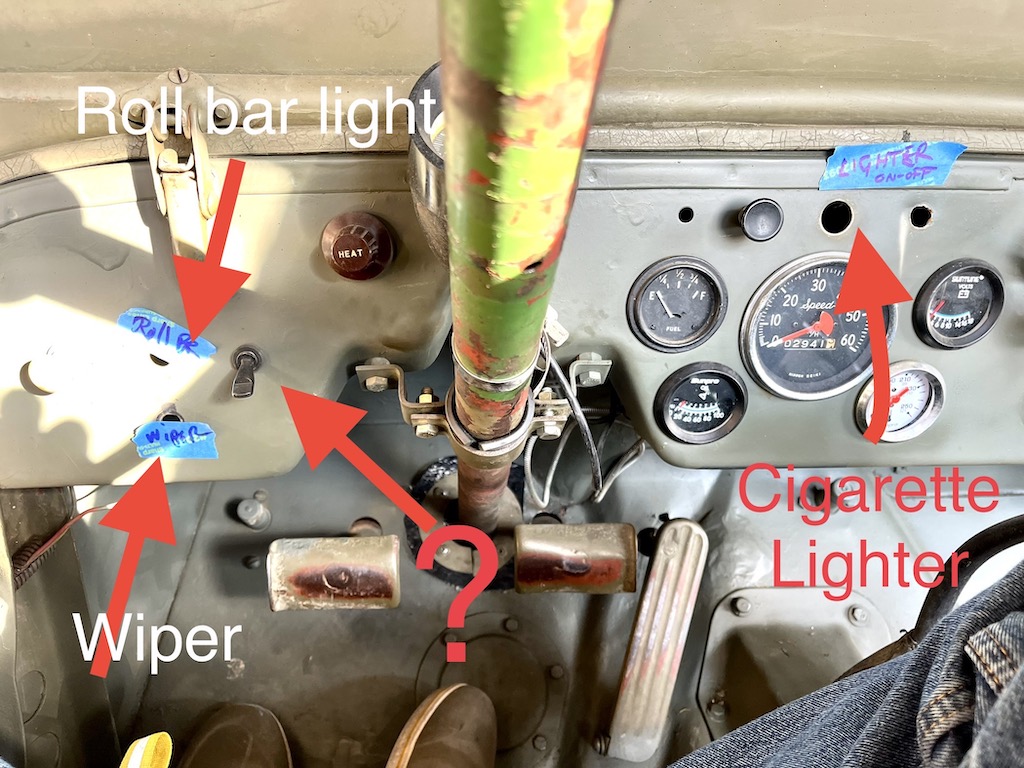

In the photo below you see holes where I removed switches for the windshield wiper (I’m going manual, baby!); the rollbar lights; and a cigarette lighter. I’ll plug the holes with some nice rubber grommets. I traced a wire from the master toggle back to the brake lights but can’t seem to make those work.

In the photo below you see holes where I removed switches for the windshield wiper (I’m going manual, baby!); the rollbar lights; and a cigarette lighter. I’ll plug the holes with some nice rubber grommets. I traced a wire from the master toggle back to the brake lights but can’t seem to make those work.

I pulled the access cover to get at the brake fluid cylinder. Didn’t have the nerve to go further. Hard to believe folks kept a close eye on brake fluid levels.

I pulled the access cover to get at the brake fluid cylinder. Didn’t have the nerve to go further. Hard to believe folks kept a close eye on brake fluid levels. While crawling around under the Jeep I noticed oil dripping from one corner of the oil pan (?). Paul thinks this might be a matter of retorquing the bolts which might have loosened up over time, or the gasket could have shrunk a small amount.

While crawling around under the Jeep I noticed oil dripping from one corner of the oil pan (?). Paul thinks this might be a matter of retorquing the bolts which might have loosened up over time, or the gasket could have shrunk a small amount.

Jeep: Test Drive #2

In this 3 1/2 min video I take the Jeep for another drive, getting used to a new shifting pattern and the overall ride. My Land Rover cruises comfortably at 40-45 mph, I don’t think I’ll be pushing the Jeep much beyond 35 mph. Have to make sure the brakes are working properly. Currently, I really have to stand on the brake to stop. Once I’m sure I can operate safely, I’ll take the Jeep onto some city streets.